|

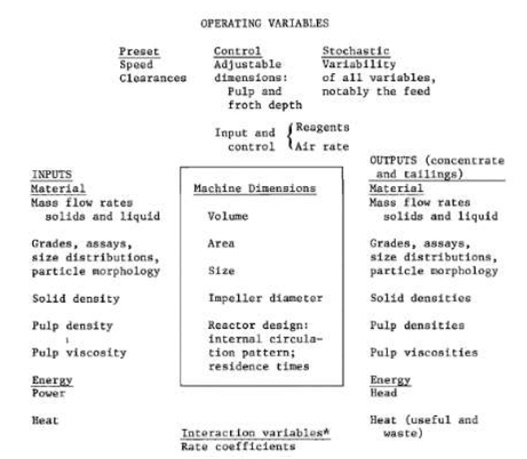

Flotation is a complex process with many variables

(Harris,

C C, 1975. Flotation Machines, in Flotation, ed. M.C.

Fuerstenau, pp 753-815 AIME: New York)

Particle

shape is one of the affecting variables on the

particle-bubble attachment

Ore grinding in froth flotation is an important step to

liberate the valuable mineral particles from the gangue

(Forssberg

et al., 1993).

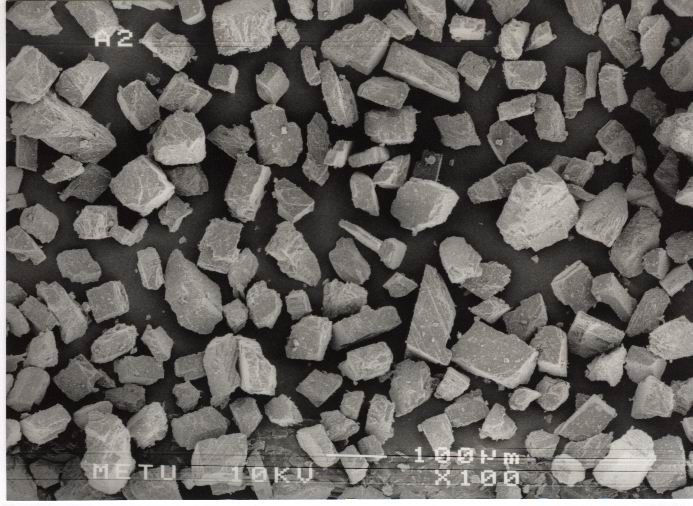

When considering particle shape in minerals processing,

comminution is of particular interest as this is the

process where the particles attain their shape which in

turn affects classification and separation stages

downstream. Studying the shape characteristics of

progeny particles can also be used to interpret breakage

mechanisms within milling devices and in some instances,

can even be related to the degree of liberation (Leroy

et al., 2011).

Particle shape can have an impact on numerous processes

through its effect on drag coefficients, rheology, and

particle bubble interactions.

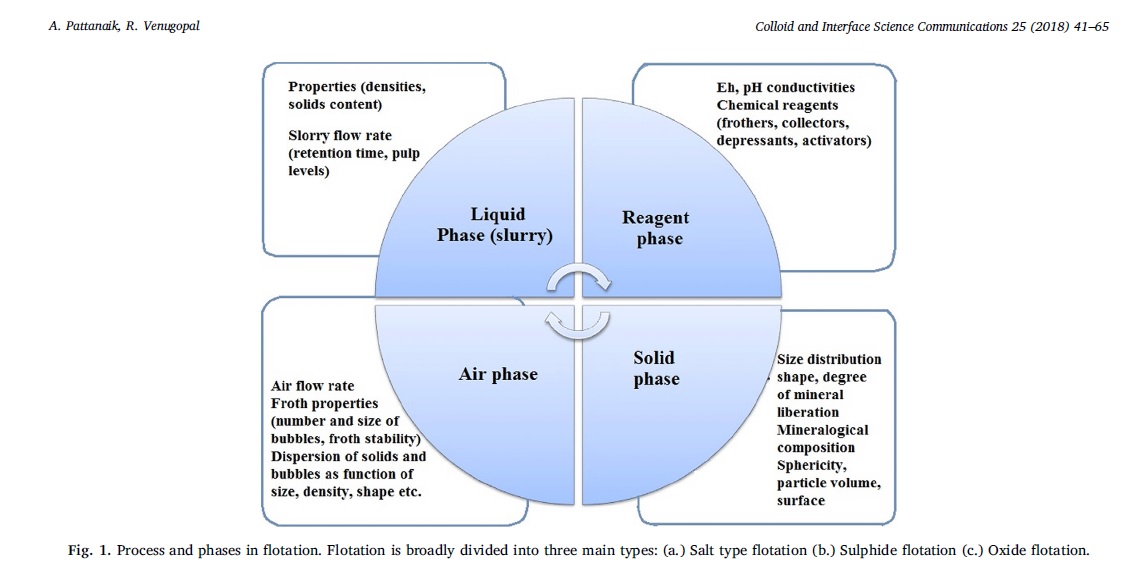

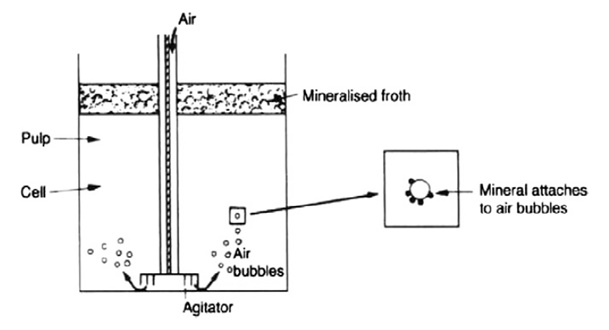

Froth flotation is a separation process which plays a

major role in the mining industry. The flotation process

essentially relies on the attachment of solid particles

on the surface of gas bubbles immersed in water.

The attachment of a solid particle on the surface of a

gas bubble can be divided into three successive stages:

the particle approach, the collision with the bubble and

the sliding down the gas–bubble interface (Schulze,

1989; Albijanic et al., 2010).

The downward sliding motion of the particle is caused by

the gravity and also by the hydrodynamic forces arising

from the local water flow around the rising bubble.

Should the particle approach the bubble surface within

the range of attractive surface forces, a thin

intervening liquid film between the gas–liquid interface

and the solid–liquid interface forms. The liquid film

eventually drains, leading to a critical thickness at

which rupture occurs (Ralston

et al., 1999). The

rupture of the liquid film results in the formation of a

stable three-phase contact (Schulze,

1992).

Figure 1. The fact that the recovery of particles by true

flotation is influenced by also particle shape has been

widely reported by some researchers

(Koh et al., 2009; Vizcarra et al., 2011; Ulusoy and

Yekeler, 2005).

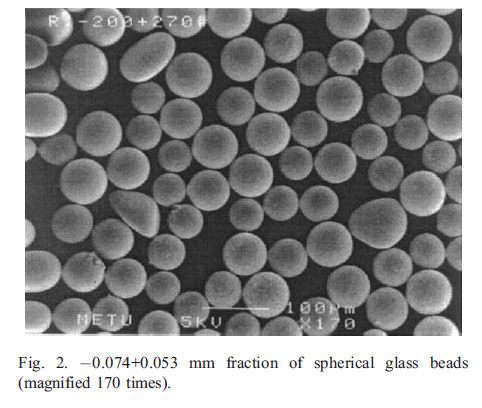

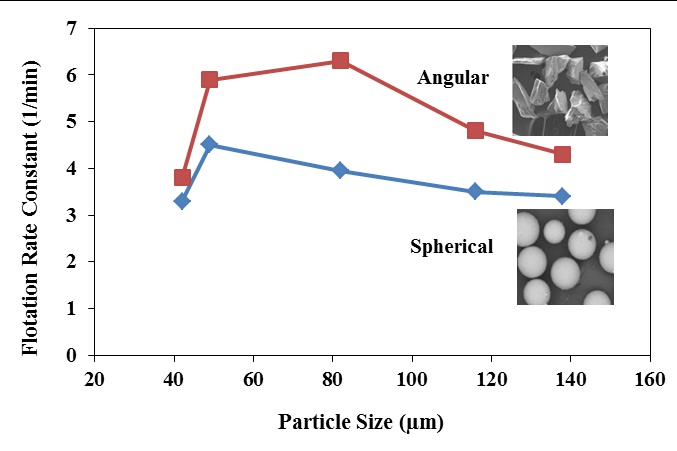

Figure 2. Flotation rate as a function of particle size

for angular and spherical particles (Adapted from

Koh et al. (2009).

Koh, P.T.L., Hao, F.P., Smith, L.K.,

Chau, T.T. and Bruckard, W.J., 2009. The effect of

particle shape and hydrophobicity in flotation.

International Journal of Mineral Processing 93(2),

128-134. |