|

Particle

surface roughness is the other ones affecting variables

on flotation

Wenzel suggested that the geometry of the surface had a

greater effect on the static contact angle than did the

chemistry!..

The

wettability of real surfaces is subject to many factors,

both physical and chemical. For the flotation process,

the effect of four main factors; surface roughness,

heterogeneity, particle shape, and particle size, on

contact angle measurements are of importance

(Chau et al., 2009).

T.T. Chau, W.J. Bruckard, P.T.L. Koh,

A.V. Nguyen, A review of factors that affect contact

angle and implications for flotation practice, Advances

in Colloid and Interface Science 150 (2009) 106–115.

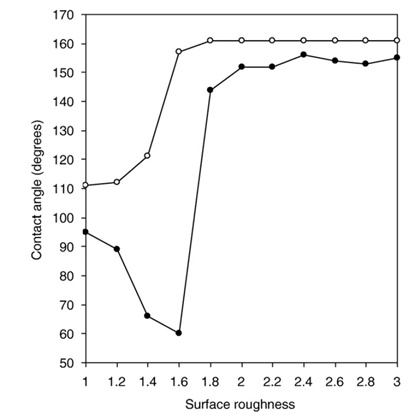

Figure:

Static contact angle ( advancing angle and the receding)

of water on wax substrates, as a function of the

substrate roughness (Johnson,

Dettre, 1964).

For hydrophobic surfaces the data of

Johnson, Dettre,

(1964),

reported in the Figure

above,

show the effects of advancing θa (maximum static angle)

and receding θr (minimumstatic angle) contact angles of

water on surfaces of wax of variable roughness.

As the roughness increases, small variations in the

angles, together with significant increases in

hysteresis, are observed. Then, both angles suddenly

increase as the hysteresis diminished. It was concluded

that texturing a solid does not only modify the

hysteresis but it can also affect dramatically the value

of the mean contact angle itself.

Johnson RE, Dettre RH. Adv Chem Ser

1964;43:112–35.

Wotruba et al. [1991]

reported contradiction results from flotation tests

carried out on zircon samples before and after

attritioning for 48h in a planetary mill. It was noted

that the particle shape remained unchanged by the

attritioning and only the particle surfaces were

roughened. It was shown that the freshly roughened

material floated in total far better than the original

material.

Wotruba H, Hoberg H, Schneider FU.

XVIIth Int Miner ProcessCong IV 1991:83–95.

Successful particle–bubble

attachment involves three steps, viz., 1) thinning of

the intervening liquid film to a (critical) thickness

where the film ruptures, 2) rupture of the intervening

liquid film and formation of a three-phase contact (tpc)

nucleus (a hole of a critical wetting radius) and 3)

expansion of tpc line from the critical radius to form a

stable wetting perimeter

(Chau et al., 2009).

T.T. Chau, W.J. Bruckard, P.T.L. Koh,

A.V. Nguyen, A review of factors that affect contact

angle and implications for flotation practice, Advances

in Colloid and Interface Science 150 (2009) 106–115.

|