|

Minerals

are critical to developing the technologies that will

propel economy, improve the quality of our lives.

The technologies that define innovation

today all depend on a growing number of minerals.

For example, in the 1980s, computer chips were

made with a palette of 12 minerals. A decade later, 16

elements were used.

Even in the information age, minerals are

used to produce telephones, computers, and televisions.

In fact, 30 different minerals are needed to make a

television or a computer and a telephone is made

from as many as 42 different minerals including

aluminum, beryllium, coal, copper, gold, iron,

limestone, silica, silver, talc, and wollastonite.

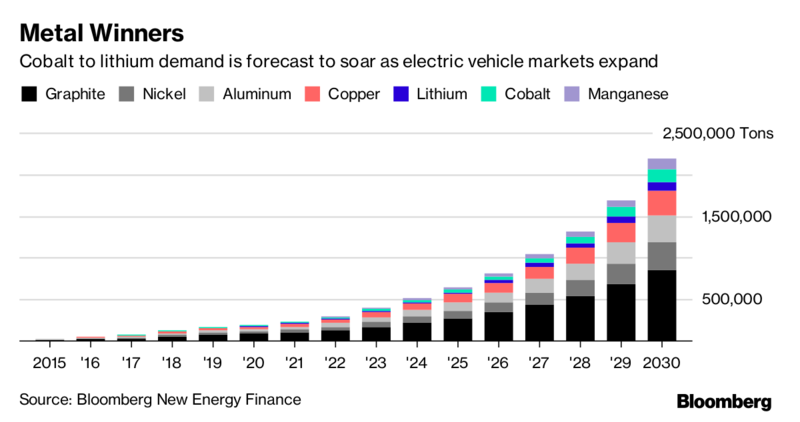

“Lithium batteries containing nickel, which helps

keep a charge over longer distances, are being installed

in electric cars from Tesla's top-of-the-line Model X to

General Motors Co modestly-priced Chevy Bolt. UBS

estimates that 15 million electric vehicles will be on

the road by 2025, lifting nickel demand by

300,000-900,000 tonnes, or by 10-40 percent of the

current market (Reuters by James Regan and Melanie

Burton).”

"Boron

plays a versatile role in our tech-driven society

from fertiliser to OLED screens. Additionally,

Neodymium magnets, in which

boron

plays a role in the formation of the crystal

structure and retaining magnetisation, are among the

strongest permanent magnets commercially available (Zhenguo

Huang, 2017)."

“According to a report presented by research firm

Wood Mackenzie, copper usage in three clean

energy sectors is expected to increase material

demand as clean energy and energy saving

technologies replace more traditional, energy-intensive

technologies. The sectors examined in the report

were renewable energy, including wind and solar;

electromobility, including electric vehicles (EVs)

and energy storage; and energy efficiency, including

electric motors, distribution transformers and air

conditioners.”

Mining

is the search for, extraction, and beneficiation and

processing of solid minerals from the earth. The kinds

of minerals extracted from the earth vary widely. For

thousands of years, these and other minerals have

provided the raw materials with which human

civilizations have been built.

The contribution that the mining

industry has made to the economic health, well being.

Mining operations are often the leading employers in the

communities where they operate (Energy

and Environmental Profile of the U.S. Mining

Industry-overview, Chapter 1 Mining Overview 2013).

Today, no mining project

is complete without carefully nurtured relations with

employees and local inhabitants, exhaustive

environmental planning and close control of all

procedures related to health and safety.

As in all

instances, progress

depends foremost upon education,

which offers no immediate fix, but it is imperative that

everything possible is done to ensure that a well

educated and safety conscious work force and a

cadre of engineers and managers capable of ensuring the

safe standards emerges

(Global

Business Reports,

Turkey

Mining 2014).

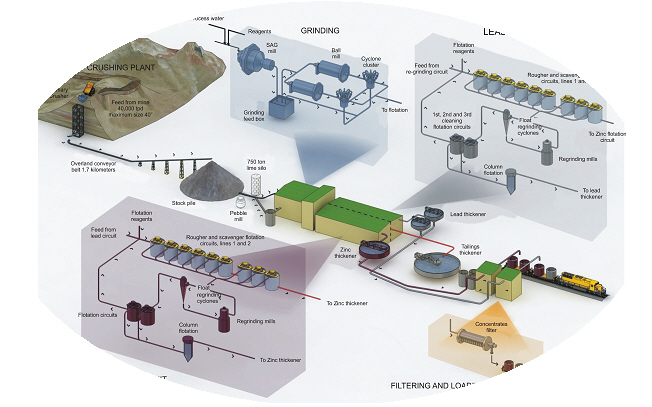

Mineral processing deals

with the variety of minerals and coal materials in a

particulates forms. It

is the process (include unit operations: comminution, sizing,

concentration and dewatering)

of separating commercially valuable minerals from

their ores.

Mineral processing operations are

generally done after beneficiation and serve to change

the concentrated mineral value into a more useful

chemical form. This is often done by using heat (e.g.,

smelting and refining) to change the chemical

composition of the mineral. Typically, beneficiation

wastes are earthen in character, whereas mineral

processing wastes are derived from melting.

Particles and

particles technologies have a profound impact on

everyday lives. It is safe to say that everyone has

dealt with particles in someway, at the same time, in

someplace in his or her everyday life. In the US alone,

the industrial output impacted by particulate systems

was almost one trillion dollars in 1993 for ten major

industries alone

(Xu, 2000).

Particle science and technology

deals with the production, characterization,

modification, handling and utilization of a wide variety

of particles in both dry and wet conditions.

|